Breakthrough FDA-approved additives blended into polymers during primary processing optimize laser marking of plastics. Fast speed, superior contrast, and cost savings are among the significant benefits. Novel chemical additives can produce jet-black, light-colored, and custom color contrast, using both “on-the-fly” and secondary operations. Designed for affordable ytterbium fiber lasers, in-line inkless laser marking now replaces traditional rotary gravure and pad printing.

Product Applications

Clear, semi-transparent, and opaque colored polymers, including nylons, polyethylene terephthalate (PET), polycarbonates, polyolefins, polyvinyl chloride (PVC), styrenics, and thermoplastic elastomers (TPUs) and thermoplastic polyurethanes (TPEs), are uniquely formulated using non-heavy metal, FDA/European Food Safety Authority (EFSA)-approved additives to achieve high-contrast marking quality (see Figure 1). Polymer clarity, spectral transmission, and base physical properties are not affected. Non-contact digital laser marking replaces expensive adhesive labels and ink-chemical printing processes. The result is a cost-effective, environmentally friendly, superior aesthetic appeal in the application.

Polymeric Laser Marking Reaction Mechanism

The advancements achieved in formulating laser chemical additives for use with near-infrared (NIR) lasers (1060–1080nm wavelength) are their compatibility with ytterbium fiber, vanadate, and predecessor Nd:YAG lasers. Most polymers do not possess NIR absorption properties without chemical additives¹. Polymers that can be marked by lasers are those that absorb laser light and convert it from light energy to thermal energy. Experts utilize additives, fillers, pigments, and dyes to enhance the absorption of laser energy for localized color changes. Vastly different formulation chemistries and laser optics/setup parameters are used depending upon the desired marking contrast and functionality.

The most common surface reaction mechanism is termed thermal chemical “carbonization” or “charring,” where the energy absorbed in the substrate raises the local temperature of the material surrounding the absorption site high enough to cause thermal degradation of the polymer. The darkness or lightness of the mark is dependent on the energy absorbed as well as the material’s unique thermal degradation pathway. By optimizing the laser setup, there is minimal surface carbonization residue.

Laser Additives

Near-infrared laser additives improve the degree of contrast, which can be further intensified by changing the laser setup parameters. Polymers possess inherent characteristics to yield “dark-colored” or “light-colored” marking contrast. Some colorant compounds containing low amounts of titanium dioxide (TiO2) and carbon black may also absorb laser light, and in some instances, improve the marking contrast. Each polymer grade, even within the same polymeric family, can produce different results. Additive formulations cannot be toxic or adversely affect the products’ appearance, or physical or functional properties.

Compared to ink printing processes (pad/screen printing and inkjet), laser additives are cost-saving and can demonstrate 20% and faster marking speeds vs. non-optimized materials. Laser additives are supplied in pellet granulate and powder form. Granulate products can be blended directly with the polymer resin, while powder forms are converted to masterbatch. Most are easily dispersed in polymers. Based upon the additive and polymer, the loading concentration level by weight (in the final part) ranges between 0.01 and 4.0%.

Both granulate and powder form can be blended into precompounded color material or color concentrate. The selection of which additive to incorporate depends upon the polymer composition, substrate color, desired marking contrast color, and end-use certification requirements. For extrusion, injection molding, and thermoforming operations, precolor compounded materials vs. color concentrate yields better uniformity. Hand-mixing should be avoided. Mold flow and gate type/location are important factors. Homogeneous distribution/dispersion of laser additives throughout each part is critical to achieve optimal marking performance.

Some additives contain mixtures of antimony-doped tin oxide and antimony trioxide that can impart a “grayish” tint to the natural (uncolored) substrate opacity. Other additives can contain aluminum particles, mixed metal oxides, and proprietary compounds. Color adjustments are made using pigments and dyes to achieve the final colormatch appearance. Commercially supplied, specific additives (also used for laser welding) have received FDA approval for food contact and food packaging use under conditions A-H of 21 CFR 178.3297 – Colorants for Polymers. For the European Union, there are similar compliance statements. Certification conditions are specific for polymer type, loading level threshold, and direct or indirect contact. Further qualification of FDA-approved additives blended into a “final part” can achieve biocompatibility of medical devices².

Nanosecond Ytterbium Fiber Laser Technology

Improvements in laser technology have been instrumental in the rapid development of the newest generation of FDA-approved laser additives. The emergence of nanosecond ytterbium fiber lasers is one of the most significant advancements for marking, welding, and cutting.

Fundamentally, fiber lasers are different than other diode-pumped solid-state (DPSS) marking lasers. With fiber lasers, the active medium that generates the laser beam is dispersed within a specialized fiber-optic cable. In contrast to fiber-delivered lasers, the entire path of the beam is within a fiber-optic cable all the way to the beam delivery optics. This all-fiber structure is largely responsible for the reliability and ruggedness of these lasers, which accounts for their rapid growth.

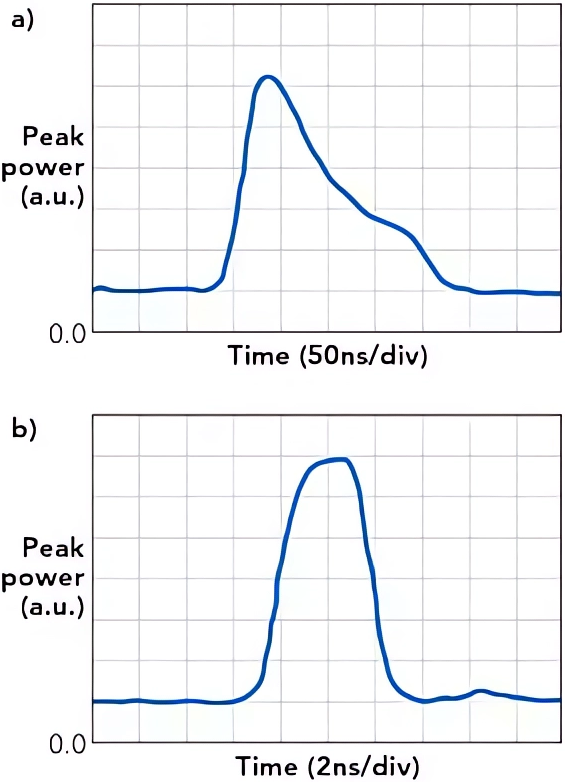

Fiber lasers yield superior beam quality (M2) and brightness compared to Nd:YAG lasers. A laser with superior beam quality can be focused to a small spot size, which leads to high energy density. Fixed- and variable-pulse master oscillator power amplifier (MOPA) fiber lasers with pulse energy up to 1mJ and high power density can mark many historically difficult polymers (see Figure 2)³.

Vanadate lasers also possess a small M2 value with shorter pulse width than fixed fiber and YAG lasers. Pulse duration influences the degree of heat and carbonization into the material. Short pulses, typically <40ns, enable more controlled energy input when processing sensitive polymeric materials. These pulses still have the peak power to overcome material thresholds, but have lower pulse energy to reduce localized thermal damage.

IPG Photonics, a leading developer and manufacturer of high-performance fiber lasers, offers both fixed-pulse YLP Series (sometimes referred to as “Q-switch”) and variable short-pulse YLPN (MOPA) lasers. Q-switched fiber lasers, typically with 100–120ns pulse width, are employed for some marking applications, but their repetition rate is limited to around 80kHz because of the inherent constraint of Q-switching technology. Directly modulated MOPA (DM-MOPA) fiber lasers can operate at repetition rates up to 500kHz at nanosecond pulse widths. High repetition rates generally translate into faster marking speed (in conjunction with other laser/waveguide parameters).

Application development is highly specific, as there is not a universal laser solution. Short-pulse-duration MOPA lasers are able to fully exploit the performance of sensitive FDA-approved chemical additives. Localized spatial and temporal control of the laser heat input and of the rate of heat input enable maximum performance. The selection of which laser type to integrate is determined by the output characteristics of the laser interacting with the optimized polymer material. FIGURE 3 represents temporal pulse shapes of fixed and variable (MOPA) pulse-length ytterbium fiber lasers [3].

When setting up a fixed-pulse-length fiber laser for marking, two inputs must be set:

- Pulse repetition rate (often referred to as pulse frequency) and

- Pump power in percent-100% refers to the maximum possible electrical input to the pump diodes.

When setting up a variable short-pulse MOPA fiber laser for marking, three inputs are set:

- Pulse duration (often referred to as pulse length);

- Pulse repetition rate (pulse frequency); and

- Pump power in percent, as explained above.

For both graphs, the particular combination of parameter inputs controls the output properties of the laser beam, namely the pulse energy, the peak power (the highest instantaneous peak of the pulse energy, joules/pulse duration), and the average power (average power in watts = pulse energy in joules × pulse repetition rate in hertz).

‘On-The-Fly’ Laser Marking

“On-the-fly” laser marking is one of the most highly specialized applications performed on molded and extruded products such as wire/cable, tubes, and pipes. Marking speeds for polyolefin synthetic wine corks and undercap promotions on linerless beverage closures are capable of 2000 pieces/min for alphanumeric text and graphics (see Figure 4). Linear marking speeds of text and machine vision codes can achieve 500 ft/min and faster, where inkless laser marking now replaces rotary gravure and pad printing.

Marking speed is a function of many variables, including polymer type, substrate color, laser additive type and loading level, cable size (weight), laser type and power, software, number of alphanumeric characters, text height, length of text string, space between characters, bar code/data matrix, logos/graphics, single-stroke or true-type filled fonts, fill direction, and continuous or repeating text. Use of the proper-formulated additive colorant will ensure that “power density” at the mark surface is not the limiting factor. Rather, the beam-steered galvanometers will be operating at maximum speed.

Because of the complexity of factors influencing on-the-fly production marking capability, every application must be precisely examined. There are few, if any, rules that can be extrapolated. However, for general purposes, consider the following nylon polymer example involving a 50W fiber laser, 254mm flat field lens, 100 alphanumeric characters, 2mm height, a repeating text string length of 14.68in., and marking time of 0.232s. The calculated speed is approximately 315 lin. ft/min.

Laser Equipment Systems

The hardware and software components a laser manufacturer incorporates into their systems makes significant difference in marking contrast, quality, and speed. A primary attribute is the power density (W/cm2) at the mark surface (which is different than the raw output power of the laser). The output mode of the laser beam is critical to the marking performance. These output modes relate to factors including the beam divergence and power distribution across the diameter of the laser beam.

Power density is a function of focused laser spot size. Focused laser spot size for any given focal length lens and laser wavelength is a function of laser beam divergence, which is controlled by laser configuration, mode selecting aperture size, and upcollimator (beam expander) magnification. Pulse repetition rate and peak power density are critical parameters in forming the mark and achieving the optimal contrast and speed. The arithmetic curves of power vs. pulse repetition rate are inversely proportional. High peak power at low frequency increases the surface temperature rapidly, vaporizing the material while conducting minimal heat into the substrate. As the pulse repetition increases, a lower peak power produces minimal vaporization but conducts more heat. Additional contributing factors that influence the marking contrast and quality are, of course, beam velocity and vector line separation distance.

Conclusion

Breakthrough FDA-approved laser additives incorporated into polymers yield superior marking contrast, line edge detail, and speed. Products incorporating laser-enhancing additives yield 20% and faster marking speeds. Benefits rapidly offset the incremental material additive cost. Advancements in affordable nanosecond ytterbium fiber laser technology have been instrumental. In-line, on-the-fly laser marking now replaces rotary gravure and pad printing. Optimized material-science chemistry for plastics laser marking requires expertise in polymers, colorants, pigments, and dyes relative to solubility, particle sizes, threshold concentration limits, color match, and regulatory certifications (GRAS, FDA Direct/Indirect Food Contact). All fiber lasers are not created equal.

Acknowledgements and References

The author acknowledges BASF Corporation’s Mark-it Laser Marking Pigment Technical Bulletin 2002, with technical content contributions from The Sabreen Group; Bruce Mulholland of Hoechst Technical Polymers and The Sabreen Group for “Enlightened laser marking,” Lasers & Optronics (Jul. 1997); and Daniel S. Burgess of Baasel Lasertechnik GmbH and The Sabreen Group for “Laser marking: A clean economical packaging solution,” Photonics Spectra (Nov. 2001).

- Sabreen, S. Fiber Lasers: Selection and Additives, Plastics Decorating, November 2017.

- Polyamide (PA) Nylon Complete Guide, SpecialChem 2019.

- Brodsky, M. Wave Forms: A New Laser Tool, Optics & Photonics, March 2012.

Scott R. Sabreen is the founder and president of The Sabreen Group, Inc., an engineering consulting company specializing in secondary plastics manufacturing processes – surface pretreatments, adhesion bonding, inkjet printing, laser marking, decorating and finishing, and product security. Sabreen has been developing pioneering technologies and solving manufacturing problems for more than 30 years. He can be contacted at 972.820.6777 or by visiting www.sabreen.com.