Adhesion Failures

Adhesion Bond Failures

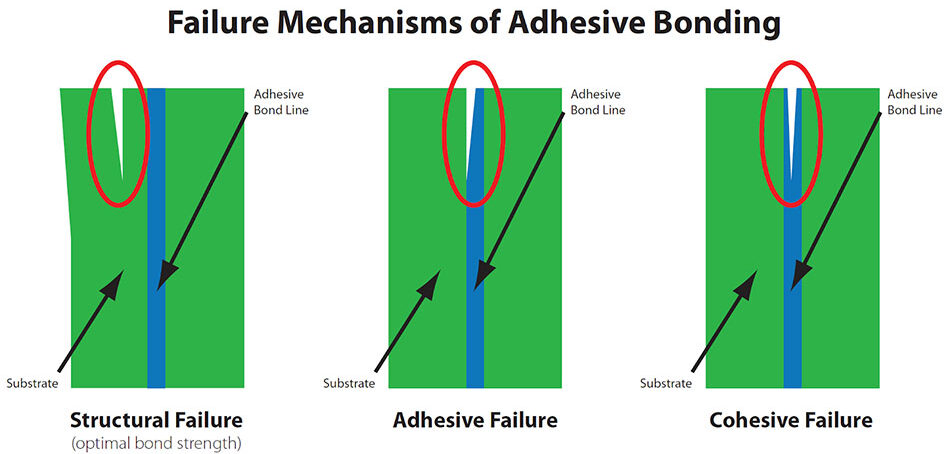

Failure Mechanisms of Adhesive Bonding

Adhesive failure is an interfacial bond failure between the adhesive (coatings, printing inks, sealants) and adherend. The failure mode refers to the mechanism by which an adhesive bond breaks or fails due to as a result of applied stress or force. Failure of adhesive bonds (delamination) can be attributable to multiple causes, such as foreign contaminants, migration of chemical additives into the adhesive bond line, viscosity and thickness attributes of the bonded interface, and environmental conditions such as temperature and water exposure. Fluctuations in temperature can generate excessive stress on adhesive bonds because of different thermal expansion properties.

The bonding process involves both adhesive and cohesive forces. The failure mode offers valuable insights into the sequential process variables that affect the strength and durability of the bonded joint. Delamination can occur at the time of manufacture or may develop during storage or service life.

Failures often involve more than one failure mode. Robust adhesive bonds must possess both bond strength and bond durability. Too often, critical failure mechanisms are not properly identified, and manufacturers end up purchasing unnecessary and costly equipment while chasing a solution.

There are four types of failure modes:

- Substrate failure (or adherend failure) is the optimal bond strength where the actual material has broken rather than the bond.

- Adhesion failuresoccur at the interface between the adhesive and the adherend (substrate). Visually, there will be residual adhesive remaining at any location on only one surface. Adhesion failures that occur in-the-field almost always originate in the manufacturing process.

- Cohesion failuresresult in fracture of the adhesive and are characterized by the visual presence of the adhesive material on the matching faces of both adherends (substrates). Cohesion failures that occur in-the-field are typically caused by poor joint design.

- Mixed-mode failures exhibit characteristics of both adhesion failure and cohesion failure because the interface is partially degraded. Essentially, this failure mode is a transitional phase in which the strength of the adhesive bond is lower than the cohesion failure strength.

Design for Manufacturing

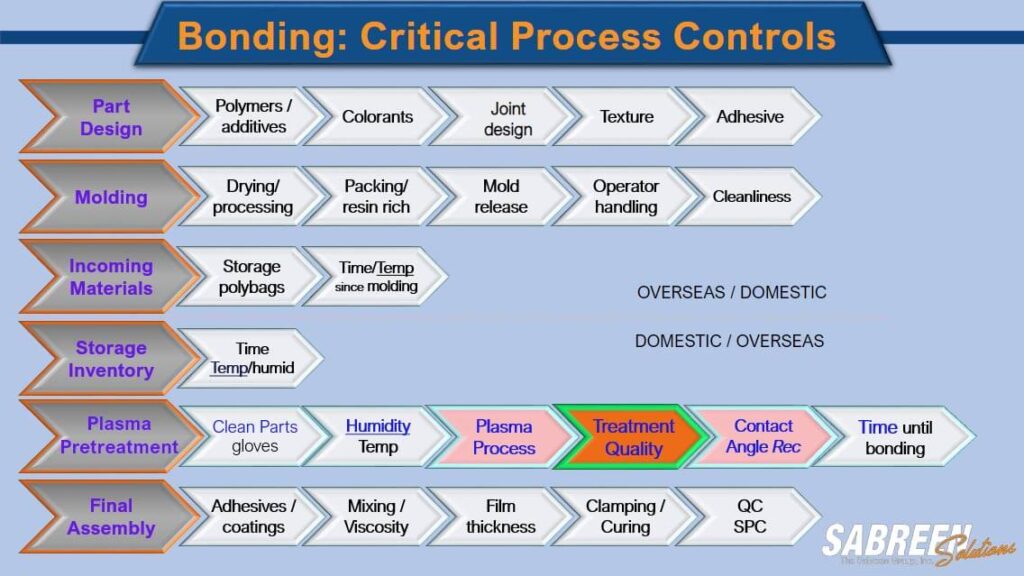

Adhesive bonds fail for a variety of reasons, including part design, molding, materials and storage, pretreatment, assembly, and operating field conditions. In today’s world of global manufacturing, components are frequently produced in one country and shipped to another for assembly. This protocol alone introduces factors that make bonding more difficult.

Adhesion bonding processes are complex and detailed, including the precise application of uniform thin adhesive bond lines, viscosity, clamping and curing, dry film thickness, texture or smooth surfaces, ambient conditions, upstream and downstream operations, and shelf-life aging. Critical Process Control Points, including in-process SPC, must be executed seamlessly.

There are many reasons why adhesive bonds can fail:

- Design – part design, joint, adhesive, assembly

- Plastic materials, plasticizers, stabilizers

- Molding, mold release, resin drying

- Over/under pretreatment, humidity/temp

- Storage, temperature, storage bags

- Harsh environment

- Sterilization methods, Photo-oxidation

Featured Webinar by Scott Sabreen

In this recorded webinar, you will gain a better understanding of the science behind surface pretreatment of different plastics and learn how to determine the best solutions for your adhesion challenges.

Topics covered:

- Adhesion versus cohesion failure

- Why pretreatments are required for low-energy plastic substrates

- Effects on adhesion from primary molding operations

- How to select the best pretreatment process

- Diagnostics, trouble-shooting and solutions

- “Best Practices” manufacturing process methods

- Real-life case studies

Quick Facts About Polymer Surfaces and Contact Angles

- Polymer morphology and processing will ultimately affect the ease or difficulty of bonding operations. Semi-crystalline plastics are generally more difficult to bond than amorphous plastics. Acetals, nylons, polyolefins, PPS, polycarbonates, PTFE, and rubber/elastomers present the greatest challenges. Migratory external lubricant sprays, such as silicones, should never be used in molding facilities because they are carried in the air to all other machines and deposited on molded parts.

- Surface preparation is critical to achieving high adhesive bond strength. Surfaces must be clean and contamination-free from dirt, grease and oils. Low molecular weight materials (LMWM) such as silicones, mold release products and anti-slip agents inhibit bonding. When cleaning plastic surfaces, excess solvent will create weak boundary layers leaving a haze build-up that will inhibit bonding. When using plasma surface pretreatment there are optimal wetting levels, overtreatment and undertreatment must be avoided.

- Contact angles and Surface Energy. Understanding the contact angle and its physical properties of interaction between solids and liquids provides valuable information in determining optimal adhesion bonding surface wettability conditions. The higher the surface energy of the solid substrate relative to the surface tension of a liquid (water, printing inks, adhesives, coatings, etc.), the better will be its “wettability,” and a smaller contact angle. Contact angles are affected by both changes in surface chemistry and changes in surface topography.

- The advancing contact angle is most sensitive to the low energy (unmodified) components of the substrate surface, while the receding angle is more sensitive to the high energy, oxidized groups introduced by surface pretreatments. Thus, the receding angle is actually the measurement most characteristic of the modified component of the surface following pretreatments, as measured using dyne solutions. Therefore it is important to measure both the advancing and receding contact angles on all surface-modified materials.

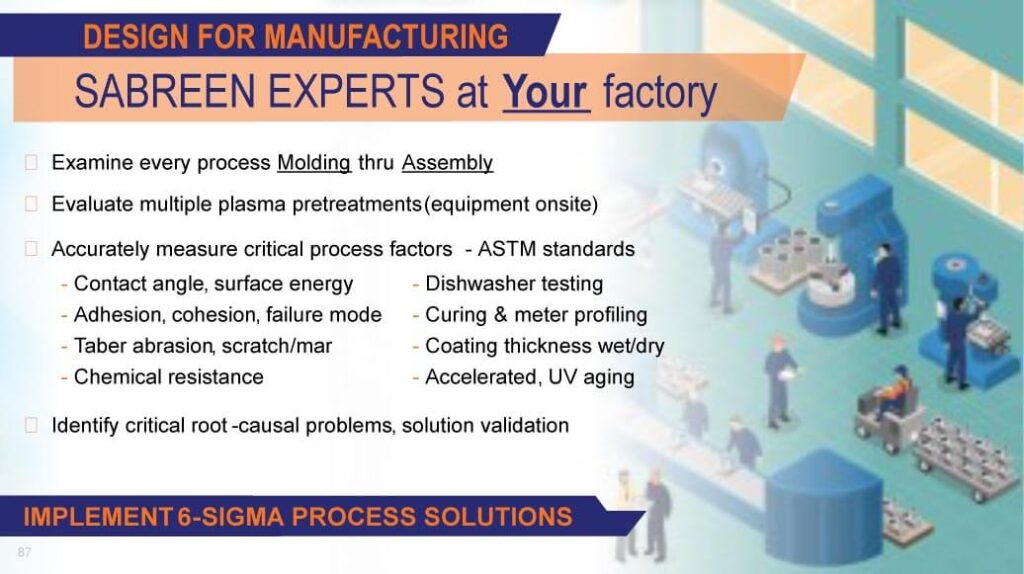

Let SABREEN’s Expertise Benefit Your Company

The SABREEN Group is widely recognized internationally as The Plastics Process Manufacturing Experts. We develop and implement robust process solutions for all types of applications, including extreme environmental reliability. From mission critical zero-defect jet fighter canopy ejection systems to drones, electronics, and underwater structures. SABREEN, with over 40 years of hands-on experience and the author of more than 100 technical publications, offers custom engineered adhesion bonding process solutions. When we work at your site, we bring plasma pretreatment and surface analysis equipment to demonstrate adhesion solutions on your production line.

Bring us your toughest challenges. Let SABREEN’s expertise bring adhesive bonding solutions to your company.