Improved Contrast, Line Edge Detail, and Speed

The newest generation of laser marking “smart additives” incorporated into polymers is a quantum leap in technology, which is both enabling and cost-saving. These advanced material science formulations achieve unprecedented marking contrast, line edge detail, and speed on plastics that have traditionally been difficult, if not impossible, to laser mark. Designed for thermal chemical surface reactions, these formulations are ideal for fiber, YAG, and vanadate lasers operating at a wavelength of 1060 to 1070 nm (near infrared spectrum).

Polymers that can be marked by lasers are those that absorb laser light and convert it from light energy to thermal energy. Since most polymers do not possess absorption properties at 1060 to 1070 nm, experts utilize additives, fillers, pigments, and dyes that enhance the absorption of laser energy for localized color changes. The material science chemistry for achieving high contrast and color laser marking is both art and science. Contrary to popular belief, a single laser additive that solves all marking problems does not exist. Vastly different formulation chemistries, laser type (fiber, YAG, vanadate), and laser optics/setup parameters are used depending upon the desired marking contrast and functionality.

FIGURE 1 shows “dark marking contrast” on polyethylene (left), “white marking contrast” on nylon (center), and custom color yellow-gold on ABS (right). It also demonstrates three unique surface reaction mechanisms. First, the charring process occurs when the energy absorbed raises the local temperature of the material surrounding the absorption site high enough to cause thermal degradation of the polymer. While this can result in burning of the polymer in the presence of oxygen, the limited supply of oxygen in the interior of the substrate results in charring of the polymer to form a black or dark marking contrast. The darkness of the mark is dependent on the energy absorbed as well as the material’s unique thermal degradation pathway. When blended into the resin colorant matrix, additives that yield dark marking contrast often contain mixtures of either antimony-doped tin oxide, antimony trioxide, or aluminum particles. All are easily dispersed in polymers. Typical loading concentration levels by weight are 0.01% to 3.0%. Many of the final formulations have received FDA approval for use under conditions A-H of 21 CFR 178.3297 Colorant for Polymers.

A second surface reaction is chemical change, through use of additives that release steam during degradation, resulting in foaming of the polymer. During the foaming process, the laser energy is absorbed by an additive that is in close proximity to the foaming agent. The heat from the absorber causes the foaming agent to degrade, releasing steam. Examples of foaming agents are aluminum hydroxide or various carbonates. To prevent charring, the mechanism requires the polymer to degrade at a temperature higher than that of the foaming additive. Through tight control of the laser-operating parameters, high quality and durable light marks can be generated on dark substrates. Poor laser control can generate a friable or low-contrast mark, which can be easily scratched (poor durability).

Third, laser energy is used to heat/degrade one colorant in a colorant mixture, resulting in a color change. An example is a mixture of carbon black and a stable inorganic colorant. When heated, the carbon black is removed, leaving behind the inorganic colorant. These mixed colorant systems are dependent on specific colorant stabilities, and not all color changes are possible.

Laser formulations cannot be toxic or adversely affect the products appearance, physical, or functional properties. They must absorb enough laser energy to raise the local temperature of the polymer to a sufficiently high level to achieve charring or foaming of the polymer, thus creating the mark. This temperature will vary for different polymers, even within a polymer family.

Achieving Faster Marking Speeds

The time required to mark a part is a function of the polymeric substrate, the number of vector lines drawn, and how fast the laser beam/galvanometer scan head draws all of the lines. Laser software and the type of vector fill, unidirectional, bidirectional or serpentine, can also affect the marking time. New independent studies are showing that statistically significant faster marking speeds are achievable by incorporating laser additive formulations at very low concentration levels, typically 0.01% to 2.0%.

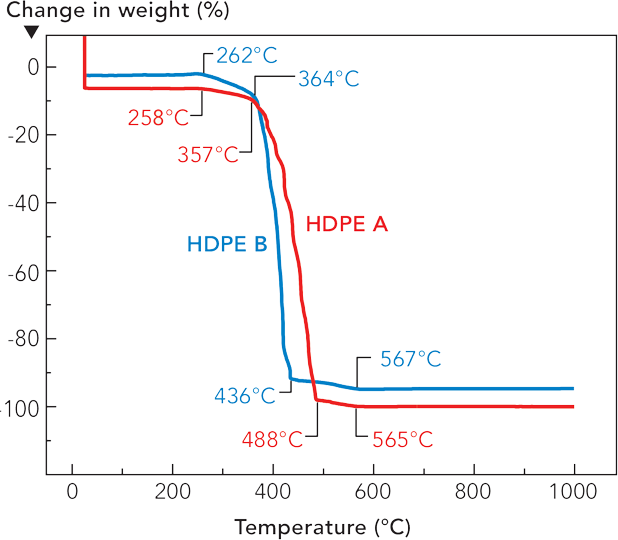

FIGURE 2 shows a thermal gravimetric analyses (TGA) plot for two high density polyethylenes. The two polymers exhibit different temperatures of thermal degradation – the process that creates the laser mark. The higher temperature polymer will require more laser energy, lower marking speeds, or more absorbing additive to achieve the same mark appearance. Smart additives are cost-saving and demonstrate 15% and faster marking speeds versus non-optimized material formulations. One interesting application is “on-the-fly” laser marking for undercap promotions on linerless beverage closures. Turnkey systems are capable of marking unique graphics and alphanumeric text at speeds up to 1,500 closures per minute. Examples are shown in FIGURE 3.

Laser Technology

The advancements in laser technology have been instrumental in the rapid development of smart laser additives. Nanosecond fiber laser technology is an emerging field and one of the most significant advancements in lasers for marking, welding, and cutting. Fiber lasers are fundamentally different than other solid state marking lasers. With fiber lasers, the active medium that generates the laser beam is dispersed within a specialized fiber optic cable. In contrast to fiber-delivered lasers, the entire path of the beam is within the fiber optic cable all the way to the beam delivery optics.

Fiber lasers yield superior beam quality and brightness. The metric for beam quality is M2 . The smaller the M2 value, the better the beam quality, whereas M2 = 1 is the ideal Gaussian laser beam. A laser with superior beam quality can be focused to a small spot size, which leads to high energy density. MOPA fiber lasers with pulse energy up to 1 mJ and high power density can mark many historically difficult polymers including nylons, urethanes, and acetals.

All beam-steered fiber, YAG and vanadate lasers are not created equal. The hardware and software components a laser manufacturer incorporates into its systems makes significant difference in marking contrast, quality and speed. A primary attribute is the power density (W/cm2 ) at the mark surface (which is different than the raw output power of the laser). The output mode of the laser beam is critical to the marking performance. These output modes relate to factors including the beam divergence and power distribution across the diameter of the laser beam. Power density is a function of focused laser spot size.

Focused laser spot size for any given focal length lens and laser wavelength is a function of laser beam divergence, which is controlled by laser configuration, modeselecting aperture size, and up collimator (beam expander) magnification. Pulse repetition rate and peak power density are critical parameters in forming the mark and achieving optimal contrast and speed. High peak power at low frequency increases the surface temperature rapidly, vaporizing the material while conducting minimal heat into the substrate. As the pulse repetition increases, a lower peak power produces minimal vaporization but conducts more heat.

Conclusion

The newest generation of laser marking “smart additives” incorporated into polymers yields unprecedented marking contrast, line edge detail, and speed. These benefits rapidly offset the incremental material additive cost. Achieving optimal material-science chemistry formulation for plastics laser marking requires expertise in polymers, property grades within polymeric families, colorants, pigments, and dyes relative to solubility, particle sizes, threshold concentration limits, color match and regulatory certifications (GRAS, FDA Direct/ Indirect Food Contact). Material-science solutions must be cost effective and easy to use, and possess no deleterious effects on the polymer’s physical and chemical properties.

References

- Engelhard Corporation Mark-it™ Laser Marking Pigment Technical Bulletin 2002, with technical content contributions from The Sabreen Group Inc.

- Bruce Mulholland (Hoechst Technical Polymers) and Scott Sabreen (The Sabreen Group Inc.), “Enlightened Laser Marking,” Lasers&Optronics, July 1997.

- Daniel S. Burgess, Scott R. Sabreen, & Carl Baasel Lasertechnik GmbH, “Laser Marking: A Clean Economical Packaging Solution,” Photonics Spectra, November 2001.

Scott R. Sabreen is founder and president of The Sabreen Group, Inc., an engineering company specializing in secondary plastics manufacturing processes – laser marking, surface pretreatments, bonding decorating and finishing and product security. Sabreen has been developing pioneering technologies and solving manufacturing problems for over 30 years. He can be contacted at 972.820.6777 or by visiting www.sabreen.com or www.plasticslasermarking.com.